The CVRT (Formaly DOE) Test is a roadworthiness test which is carried out on light commercials bellows 3500kgs gross on an annual basis. We have been carrying out this test since 1981.

The LCV test covers vehicles up to 3500 Kgs gross. This is the test category that the majority of commercial vehicles fall into. This test is applicable to most vans and light trucks. If a vehicle can be driven on a category "B" car licence then this is the test you require to tax your vehicle.

Preparing for your light CVRT Test

The CVRT test is a structured test. That means the testers follows a set routine using specific equipment to acertain the condition of a vehicle. From this sequence the tester determines the current working condition of the vehicle and either issues a pass certificate or advises a retest. While you may not be a mechanic or have much experience with commercial vehicles there are a number of things that you can do prior to your test to prepare your vehicle for examination. The reasoning behind this is that it is fruitless to bring a vehicle for test and find that you need a retest for something that you could have rectified yourself before bringing your vehicle in.

Below, we have outlined some of the major areas that you can have a look at yourself prior to the vehicle test and some simple ways to maximise your chances of getting a pass certificate.

Engine and Coolant Levels.

If you run a van or truck you should be familiar with the location of the oil and coolant indicators on your vehicle. It is common enough for vehicle to come for test with very low levels of oil or coolant. This is a problem for the tester as he needs to smoke test the vehicle. A smoke test measures the CO2 emmisions of the vehicle and tells the tester how efficiently the engine is burning fuel. The smoke test is carried out while the engine is hot. It is measured at both Idle and fast (around 3000 Rpm) engine speeds. If a vehicle is very low on oil, the tester will be running a risk of damaging the engine while performing the test. So if a vehicle is seriously low on oil, the tester cannot carry out the smoke test. In days past it was a simple matter of topping up the oil and carrying on. However with the advent of Euro 4 and Euro 5 engines the oil type in an engine can vary greatly and needs to be kept to manufacturers' specification.

The bottom line is:

Coolant levels are also important for the same reasons as outlined above, checking coolant can be a little more in-depth than the oil, depending on vehicle type. Vans and jeeps typically have an expansion tank in the engine bay. Usually these tanks are translucent with max and min markers. This means you can quickly tell if your coolant levels are high enough. With trucks, the expansion tank is usually mounted externally on the cab, they quite often only have a window and float to show you the level of fluid. On larger vehicles it also makes sense to check the level in the radiator, there is usually a cap on the radiator or close-by that you can check. Perform all coolant checks on a cold engine to avoid injury.

Lighting and Electrical.

Again a very commom occurance when presented for test are vehicles with lights that are not functioning. Its best to get a friend to help you with this check. Starting with the vehicle side lights, ensure all are functioning. Move onto main beams and then brake lights, indicators and finally reversing lights. There are 2 main causes of lights not working,

Firstly bulbs themselves are prone to failure but easily replaced.

Secondly are blow fuses. Most vehicles have a number of spare fuses located in the main fuse box of the vehicle. Your vehicle manual will show you the location of the fuse box and the relevant fuse for the light that is not functioning.

Tyres

The CVRT test involves a check of tyre condition. This is an examination of tyre thread and condition. Tyre threads should be above 1.5mm and evenly worn. Uneven wear is a problem that occurs on many vans and trucks with rigid front axles. Cornering and loads can cause excess thread wear on the extremities of the tyre. A proactive way of dealing with this is to get your tyres rotated on a regular basis. This involves swapping the tyres from the front to the rear. Rear tyres tend to wear evently as there is less torsional pressure on the tyres. When getting your vehicle serviced you should ask your garage to perform this for you.

Tyre condition involves checking the side walls for impact damage and bulges. Weathering of tyres can occur when they are quite old. They lose natural oils and develop cracks. Cracks and sidewall damage are the major causes of blow outs.

Prior to bringing your vehicle in for inspection you can check the tyres for wear and inspect the sidewalls yourself and replace if needs be. It is also a good time to check your tyre pressure. Tyre pressure recommendations are usually on the tyres themselves but you can also check the driver's door frame on the vehicle. Normally there will be a sticker with the manufacturer recommendation of tyre index and operating pressure.

Keeping your tyre pressures in this range can:

Braking and Suspension.

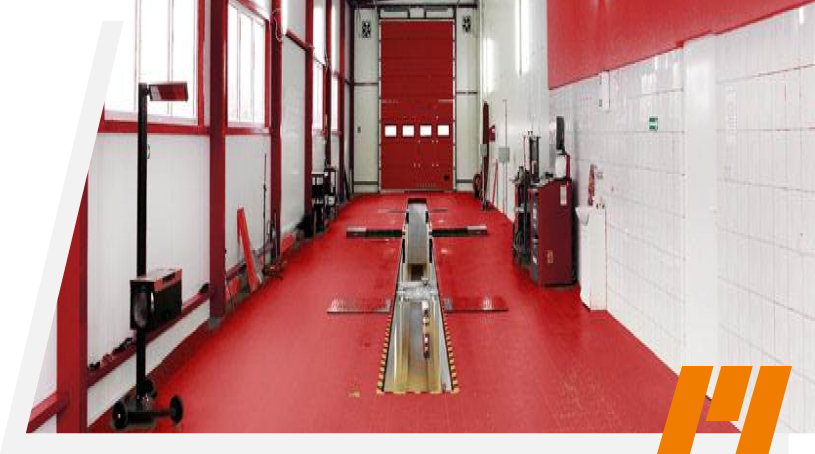

This is a difficult area for a vehicle user to examine without specialised equipment. A major component of the test is the braking performance of the vehicle. The braking performance is measured on the vehicle under a load simulation, the purpose of this is to check how efficient the braking is at stopping a laden vehicle. The handbrake performance is also checked. Generally if the brakes on a vehicle are sub par, the owner will be aware of it. You can usually examine the condition of the brake disc and pads with the aid of a flashlight. If the brake discs have grooves on the surface, this can indicate that they are at the end of their usable life and that the pads could be low also.

On the suspension front, vehicles are checked for component wear. Kingpins, ball joints and bushes are visually inspected and then tested on hydraulic plates to simulate movement under load. If your vehicle suspension feels tired, it is usually an indication of worn out components. Again this is something that is difficult for the average user to check.